Turbine Cooling Group

Turbine Cooling Group

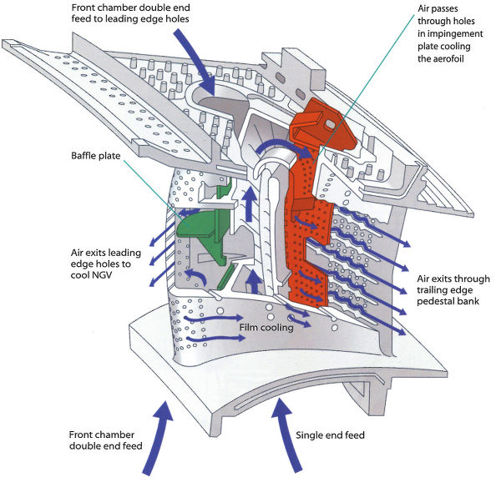

In order to increase the fuel efficiency of civil turbofan engines, manufacturers have continued to increase the operating temperatures and pressures of new engine designs. Current designs feature high pressure turbine entry temperatures that far exceed the blade material melting point and thus require the use of air cooling to maintain an acceptable metal temperature and component life.

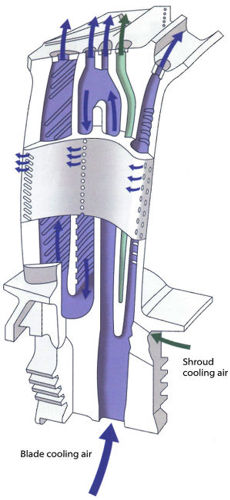

Typically, blade cooling is accomplished through a mixture of internal cooling to reduce the metal temperature from within, and external film cooling to shield the exterior surface from the hot mainstream gas. This use of air is detrimental to engine efficiency since a reduced amount of work is extracted from it by the engine. Furthermore, the cooler air ejected via films back into the mainstream gas path reduces the temperature of the gas, reducing the amount of power that can be extracted by later turbine stages. This means that if the amount of cooling air required becomes too large, the reduction of efficiency due to cooling can outweigh the increase in efficiency due to a high turbine entry temperature.

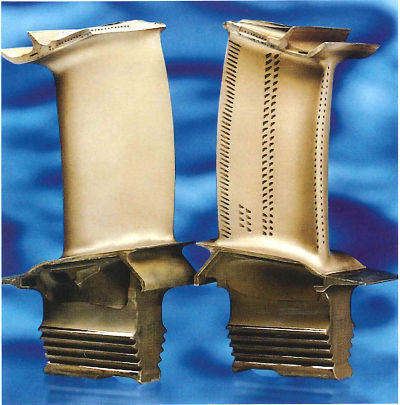

The turbine cooling group uses a variety of experimental techniques involving pressure sensitive paint, thermochromic liquid crystals and infra-red cameras to measure the performance of both industry standard and novel cooling designs. These are used to validate numerical models and understand the merits and drawbacks of each design feature.