Oxford Thermofluids Institute | Facilities - Step Climb Transient Heat Transfer Facility

Transient Heat Transfer Facility

Transient Heat Transfer Facility

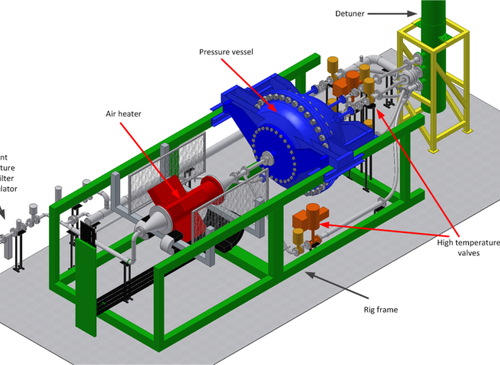

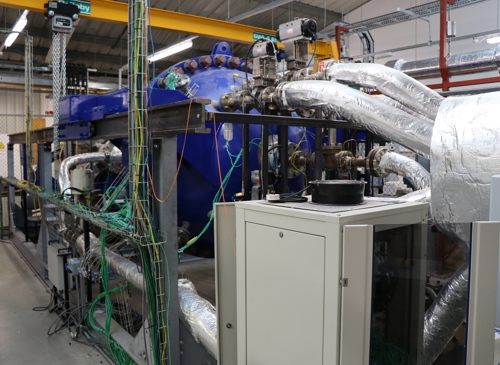

The Transient Heat Transfer Facility (THTF) is a facility capable of reproducing 3-D full-scale flow conditions in a large civil aero engine high-pressure turbine segment cavity, at true cruise secondary air system temperatures, pressures and mass-flows. Although the present design of the facility has been described in the context of simulating airflows and heat transfers in the HP turbine segment cavity, the modular approach employed here enables line replaceable geometry changes.

The facility has been inspired by the need to better understand the circumferential heat transfer of air system flows on the casing. Understanding heat transfer rates both spatially and temporally, enables better prediction of the achievable tip clearance accuracy and its likely impact on turbine efficiency.

Normally, estimation of the heat transfer rates requires substantial and costly instrumentation during an engine development program backed with months of analysis. To complicate matters further, as a result of long manufacturing lead times, only small variations to the mechanical design are possible once the analysis from such experiments is complete. This severely impacts either the achievable tip clearance or results in a compromise in terms of air system consumption/case-cooling flows.

One of the aims for this facility is to enable rapid prototyping of various segment configurations so that an understanding of the likely leakages/heat transfers can be used to optimize the design for tip clearance.